A small Canadian company’s new way of extracting gold and other precious metals is showing big promise for the mining industry, and for efforts to deal with the growing problem of electronic waste.

The CEO of Vancouver-based EnviroLeach Technologies says the new approach is also the biggest innovation for conventional gold mining in 150 years.

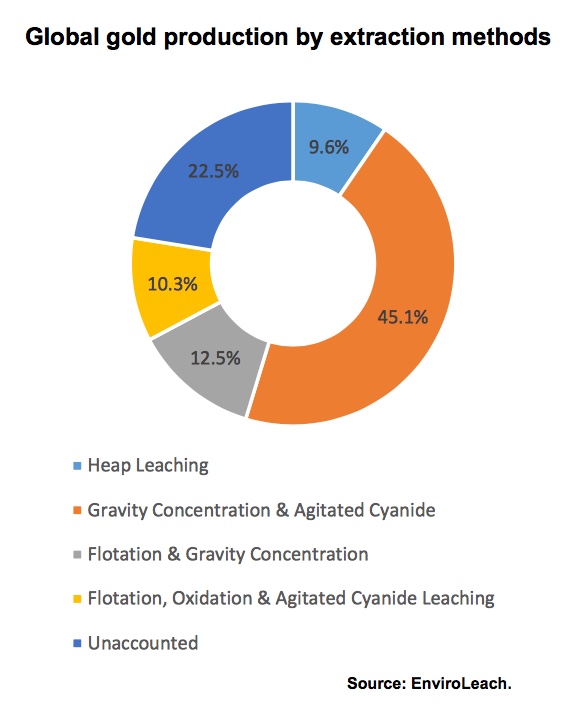

“The advent of cyanide in the 1870’s was the biggest innovation in all of mining history, and this challenges that,” says Duane Nelson. “Our technology has equal-to or better leach kinetics than cyanide, and a much broader base of available ores and concentrates that it can be used on. So this is potentially a game changer for the mining sector.”

New water-based extraction process aims to become an alternative to acid- and cyanide-based leaching.

EnviroLeach’s new plant, a joint venture with electronics giant Jabil Inc., will open in December in Memphis, Tennessee. The 650,000 square foot plant will shred and pulverize discarded circuit boards and other electronic waste. Then, using proprietary technology, Jabil will extract gold and other precious metals from the e-waste to manufacture electronic components for Dell, Hewlett-Packard and other clients.

Because it’s water-based and uses harmless ingredients, Nelson says the process is far more environmentally friendly than extraction by cyanide, hot acid digestion or other conventional methods.

“You can put your hand in it,” says Nelson. “You can effectively drink the stuff,” he says, adding it’s also less expensive because the solution can be used repeatedly.

Applying inorganic electro-chemistry research methods, Nelson says EnviroLeach’s team of 20 scientists “stumbled upon” the new technique. Ore concentrate or pulverized e-waste is mixed with ordinary water containing five ingredients. The solution is then pumped through cells of small, man-made diamond plates and then zapped with electricity. The gold and other precious metals separate and are extracted from the solution, which can be recharged and used again.

With environmentalists pressuring governments to deal with the growing mountains of e-waste around the world, EnviroLeach and Jabil shareholders see huge profits in recycling the 50 million tonnes of e-waste dumped in landfills every year.

With environmentalists pressuring governments to deal with the growing mountains of e-waste around the world, EnviroLeach and Jabil shareholders see huge profits in recycling the 50 million tonnes of e-waste dumped in landfills every year.

But Nelson says the new process can also unlock riches for conventional mining. Unlike cyanide or hot acid digestion, Nelson says the new process doesn’t damage equipment. More importantly, it could be used in locations where cyanide is banned.

“So there are hundreds of mines out there that could benefit from this technology,” he says.

Does cheap, effective and environmentally safe mining sound too good to be true? Nelson has this response for the skeptics.

“You know, cyanide sounded too good to be true in the 1800’s. Personal computers sounded too good to be true,” he says. “It’s innovation, and the mining sector has not been one of the most innovative sectors out there.

“The environment will benefit, the mining sector will benefit, our shareholders will benefit. I think everyone is going to benefit from this.”